Classic

Airframes 1/48 A5M4-K Claude Trainer

Classic

Airframes 1/48 A5M4-K Claude Trainer

By John C. Valo

Having worked with Classic Airframes on various projects, and having built a few of their kits, I was delighted to have been asked to build up an example of the new A5M4-K Claude trainer to provide a review article. CA rather specializes in less than run-of-the-mill subjects, but this one is way out there! I can't say I have an overabundance of reference material on this particular airplane, so I won't even try to comment on the history here. Suffice it to say that for cramming two cockpits into a small single-seat design, the result isn't as inelegant as it probably could have been, and the CA kit captures the lines and 'sit' of the airplane quite well.

To

keep things fresh, I like to start with different assemblies for each

new project. I admit to having always started on the cockpits whenever

I built a model, but the only result was a workbench scattered with really

nice cockpits when my enthusiasm for a given model waned. For the Claude,

I decided to start with the engine, which is a beautifully molded multi-piece

resin affair. The instructions provide a suggestion for adding pushrods

from styrene rod or wire, and as it was being assembled, I could not help

but to embellish with a simple ignition harness. A little wash, a little

dry-brushing, et voila!

To

keep things fresh, I like to start with different assemblies for each

new project. I admit to having always started on the cockpits whenever

I built a model, but the only result was a workbench scattered with really

nice cockpits when my enthusiasm for a given model waned. For the Claude,

I decided to start with the engine, which is a beautifully molded multi-piece

resin affair. The instructions provide a suggestion for adding pushrods

from styrene rod or wire, and as it was being assembled, I could not help

but to embellish with a simple ignition harness. A little wash, a little

dry-brushing, et voila!

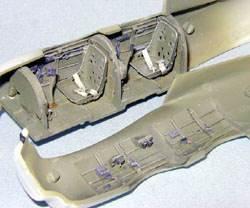

Once satisfied with the engine, I moved on to the cockpit. The resin

cockpit is quite nice, although I did heed the advice provided in Step

1 of the instructions and shaved the rear instrument panel from part R9,

gluing it to the back of part R7. Although the instructions show the cockpit

parts being assembled as a tub, I elected to build up the floor and bulkheads

first, fitting and adjusting these to match the cockpit openings. I then

glued one set of the resin cockpit sides to the fuselage halves, then

dry-fit and assembled the remaining cockpit parts as I went. A word of

advice - dry fit all the  parts

before painting and detailing, as there will be some trimming involved!

I narrowed the cockpit floor so it would fit farther forward in the fuselage,

which helped align the instrument panel bulkheads and seats with the cockpit

openings. Depending on how you approach the assembly, fitting and a bit

of sanding will be necessary to make sure all those parts fit into the

proper place. After all, just like the real thing, this is a two-place

cockpit going into a one-place airframe that wasn't horribly spacious

to begin with! Note that immediately following that inserting the fuselage

underside spacer eases the fit of the cockpit parts mentioned below. I

painted the cockpit parts with a generic khaki-grey, and picked out the

details in various colors. The only addition to the kit parts were seatbelts

made from electrical tape. With all parts in place, the fuselage halves

were joined together. Again, the instructions suggest sanding the mating

edges of the rear fuselage upper parts, as the fin/rudder (part A7) is

slightly narrower than the fuselage at its seam. Not much thinning has

to be done, but be sure to test fit the fin/rudder as you go so you don't

remove too much. I added a small clear lamp to the end of the fuselage

made from a piece of clear sprue. Per the instructions, the unnecessary

tailhook fairing was sanded off.

parts

before painting and detailing, as there will be some trimming involved!

I narrowed the cockpit floor so it would fit farther forward in the fuselage,

which helped align the instrument panel bulkheads and seats with the cockpit

openings. Depending on how you approach the assembly, fitting and a bit

of sanding will be necessary to make sure all those parts fit into the

proper place. After all, just like the real thing, this is a two-place

cockpit going into a one-place airframe that wasn't horribly spacious

to begin with! Note that immediately following that inserting the fuselage

underside spacer eases the fit of the cockpit parts mentioned below. I

painted the cockpit parts with a generic khaki-grey, and picked out the

details in various colors. The only addition to the kit parts were seatbelts

made from electrical tape. With all parts in place, the fuselage halves

were joined together. Again, the instructions suggest sanding the mating

edges of the rear fuselage upper parts, as the fin/rudder (part A7) is

slightly narrower than the fuselage at its seam. Not much thinning has

to be done, but be sure to test fit the fin/rudder as you go so you don't

remove too much. I added a small clear lamp to the end of the fuselage

made from a piece of clear sprue. Per the instructions, the unnecessary

tailhook fairing was sanded off.

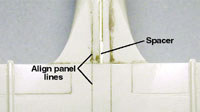

Moving

on to the main structural assembly, about the only real fit problem that

I encountered was when dry-fitting the lower wing to the fuselage halves.

Gaps at the wing roots obliged me to insert a small (1 mm / .030") spacer

between the fuselage halves at the lower seam, immediately behind the

wing/fuselage joint. There are two panel lines that run lengthwise on

the underside of the fuselage halves that will match up to their counterparts

on the lower wing when the spacer is inserted. After doing this, the wing

roots only needed a touch of the sanding stick for a good fit. I filled

the resulting gap between the fuselage halves with putty, and all was

well. This also dramatically assisted the fit of the cockpit parts. This

particular point has been reflected in the instructions also. Having not

yet built the single-seat Claude, I have no idea if the same situation

exists, but it certainly is an easy fix, and would be worth checking into

if building the single-seater. Once the wings were in place, I cut away

the navigation lights and replaced these with new ones carved from colored

toothbrush handles. Optional resin aileron actuators are

Moving

on to the main structural assembly, about the only real fit problem that

I encountered was when dry-fitting the lower wing to the fuselage halves.

Gaps at the wing roots obliged me to insert a small (1 mm / .030") spacer

between the fuselage halves at the lower seam, immediately behind the

wing/fuselage joint. There are two panel lines that run lengthwise on

the underside of the fuselage halves that will match up to their counterparts

on the lower wing when the spacer is inserted. After doing this, the wing

roots only needed a touch of the sanding stick for a good fit. I filled

the resulting gap between the fuselage halves with putty, and all was

well. This also dramatically assisted the fit of the cockpit parts. This

particular point has been reflected in the instructions also. Having not

yet built the single-seat Claude, I have no idea if the same situation

exists, but it certainly is an easy fix, and would be worth checking into

if building the single-seater. Once the wings were in place, I cut away

the navigation lights and replaced these with new ones carved from colored

toothbrush handles. Optional resin aileron actuators are  provided

if you choose to carve off the ones molded onto the wings. I elected to

do so, and I think the result is well worth the minimal effort involved.

The stabilizers, engine and cowl were affixed in place, then it was into

the home stretch.

provided

if you choose to carve off the ones molded onto the wings. I elected to

do so, and I think the result is well worth the minimal effort involved.

The stabilizers, engine and cowl were affixed in place, then it was into

the home stretch.

For the fixed landing gear, CA provides two styles of wheel spats, a

full spat (as on the fighter version) and a cut-back variation. I have

not seen photos of the particular arrangement that CA has provided for

the cut-back version, but it certainly is conceivable that this arrangement

was used. From a 'model' standpoint, this is a whole lot easier to build

(and I'm quite sure, manufacture) than the most commonly photographed

'bare strut with a couple of pieces of tin attached' variant. As I wanted

to build this kit essentially as it came in the box, I used the parts

provided. I would advise sanding the mating edges of the constituent parts

of the spats on a flat piece of  sandpaper,

occasionally checking the fit of the wheel between the spat halves. I

only recommend this because I didn't, and wound up with a slight, almost

unnoticable, mismatch between the port and starboard spats. Live and learn!

sandpaper,

occasionally checking the fit of the wheel between the spat halves. I

only recommend this because I didn't, and wound up with a slight, almost

unnoticable, mismatch between the port and starboard spats. Live and learn!

The kit provides markings for two aircraft, one in overall yellow-orange, and one in dark green over yellow-orange. I elected to do the former, to add a splash of color to my collection. I gave the model a final once-over with fine sandpaper, primed, and painted it overall with Polly-Scale paints mixed to the appropriate yellow-orange. The sweeping anti-glare panel was masked and painted in a blue-black mix. Future was used as a pre-decal clear coat, and the Microscale decals went on without a problem, snuggling into the panel lines beautifully after the application of some Micro-Sol. I attached the styrene-sheet airflow fences after applying the decals, then matched the touch-up paint to the decal colors. All panels lines were given an oil wash, then the model was given a final Polly-S satin clear coat.

Two

sets of windscreens are provided (one spare of each), and these were attached

using white glue and framed with strips of pre-painted electrical tape.

The forward windscreen fit fine into the molded areas on the fuselage;

the rear windscreen needs some trimming and test fitting, so take your

time. A hole has to be made in the forward panel of the rear windscreen

to allow the rollover fairing to protrude through, which I added after

the windscreens were in place. The propeller consists of resin hub and

plastic blades that benefit from some thinning at the tips. Although the

instructions suggest drilling the hub out to attach the blades, I simply

glued the blades on as a butt joint. Adding the pitot tube, tailwheel

and drop tank finished the job.

Two

sets of windscreens are provided (one spare of each), and these were attached

using white glue and framed with strips of pre-painted electrical tape.

The forward windscreen fit fine into the molded areas on the fuselage;

the rear windscreen needs some trimming and test fitting, so take your

time. A hole has to be made in the forward panel of the rear windscreen

to allow the rollover fairing to protrude through, which I added after

the windscreens were in place. The propeller consists of resin hub and

plastic blades that benefit from some thinning at the tips. Although the

instructions suggest drilling the hub out to attach the blades, I simply

glued the blades on as a butt joint. Adding the pitot tube, tailwheel

and drop tank finished the job.

Overall,

I was very pleased with this kit, and anyone who is familiar with building

limited-run kits of this nature shouldn't have any problems correcting

the minor fit problems. Being an aficionado of the weird and wonderful,

I am generally happy to trade a few minutes of my time for the opportunity

to add such a bizarre contraption to my collection. I found that this

model has certainly whet my appetite for the single-seat version of the

Claude that CA released earlier - I'll have to work that into the schedule

somehow! Recommended to the experienced limited-run builder.

Overall,

I was very pleased with this kit, and anyone who is familiar with building

limited-run kits of this nature shouldn't have any problems correcting

the minor fit problems. Being an aficionado of the weird and wonderful,

I am generally happy to trade a few minutes of my time for the opportunity

to add such a bizarre contraption to my collection. I found that this

model has certainly whet my appetite for the single-seat version of the

Claude that CA released earlier - I'll have to work that into the schedule

somehow! Recommended to the experienced limited-run builder.

Previous: Contents