Eastern Express 1/72nd T-34/76 Model 1942

By James D. Gray

|

|

Construction

Soviet

armor in the Great Patriotic War seems quite standardized when you first

start to learn about it, but as you immerse yourself in the details

more and more variability appears. The T-34's produced in 1943, for

example, had four different types of turret, functionally identical

but visually distinct. It's these sorts of details that can help you

to make your model different from what comes out of the box. Soviet

armor in the Great Patriotic War seems quite standardized when you first

start to learn about it, but as you immerse yourself in the details

more and more variability appears. The T-34's produced in 1943, for

example, had four different types of turret, functionally identical

but visually distinct. It's these sorts of details that can help you

to make your model different from what comes out of the box.

Construction began with the turret, which goes together very well.

The turret hatches are unfortunately molded shut, so I cut out the commander's

hatch and made a new hatch cover from sheet plastic. I wanted to pose

a figure there. I also drilled out the 76mm gun and the machine gun

barrels. There is a vision slit on each side of the model turret, but

the real ones seem to have a raised lip around them which the kit did

not include. I built up this lip with  several

coats of thick paint. I carefully cleaned up the glue line where the

upper and lower halves of the turret join. This proved to be a mistake.

There is a prominent mold parting line here in the real thing, which

the Soviets didn't waste time cleaning up very well. I had to put this

back on with stretched sprue which I then filed when dry to make a rough

line. The most delicate detail on the turret, the lifting rings, were

produced from fine wire and glued into holes drilled in the turret roof. several

coats of thick paint. I carefully cleaned up the glue line where the

upper and lower halves of the turret join. This proved to be a mistake.

There is a prominent mold parting line here in the real thing, which

the Soviets didn't waste time cleaning up very well. I had to put this

back on with stretched sprue which I then filed when dry to make a rough

line. The most delicate detail on the turret, the lifting rings, were

produced from fine wire and glued into holes drilled in the turret roof.

The new Eastern Express T-34 comes with what Steven Zaloga calls the

"softedge turret". Looking at every T-34 photograph I could

find seems to suggest that this was the least common style of turret,

which will put a crimp in the markings you can choose from.

The

hull and its various features took up a lot more time. Basic construction

was pretty straightforward; typical of Eastern European kits, it is

built up of flat plates. Just be sure everything is nice and square

and there will be few problems. A good modeller will fill the gaps under

the fenders with sheet plastic but since I was doing this kit instead,

I squirted in a lot of Green Stuff and sanded it down afterwards. It

does not have to be a very neat job since this area is difficult to

see after the tracks are installed. The join where the glacis plate

meets the lower hull is sharp, but this is only correct for the later

T-34-85; it should be rounded. This is easy enough to fix with a file

and sandpaper. The hull side plates will need some shims or filler to

match up with the upper hull plate. The two final transmission covers

at the hull rear don't fit very well at all and need some cunning use

of filler. I used multiple applications of paint, which is easier to

control but takes infinite patience. I made a mistake and matched these The

hull and its various features took up a lot more time. Basic construction

was pretty straightforward; typical of Eastern European kits, it is

built up of flat plates. Just be sure everything is nice and square

and there will be few problems. A good modeller will fill the gaps under

the fenders with sheet plastic but since I was doing this kit instead,

I squirted in a lot of Green Stuff and sanded it down afterwards. It

does not have to be a very neat job since this area is difficult to

see after the tracks are installed. The join where the glacis plate

meets the lower hull is sharp, but this is only correct for the later

T-34-85; it should be rounded. This is easy enough to fix with a file

and sandpaper. The hull side plates will need some shims or filler to

match up with the upper hull plate. The two final transmission covers

at the hull rear don't fit very well at all and need some cunning use

of filler. I used multiple applications of paint, which is easier to

control but takes infinite patience. I made a mistake and matched these

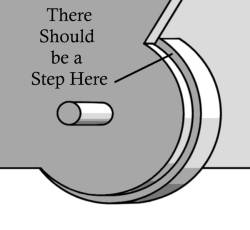

housings

up with the hull-side pieces too well; there's supposed to be a step

there, but I sanded it flush. The fenders are rather thin but still

not scale thickness, so I scraped and sanded them down, and then carefully

bent them up by heating them with a candle and applying some needle-nose

pliers. It's easy to do but easy to mess up as well. Too much heat and

they melt, and the pliers sometimes leave marks that have to be filled.

This method tends to round the corners on the fenders a bit, but if

you are careful it's nothing a few swipes with the edge of a hobby knife

won't fix. Also I cut off one of the front fenders. Soviet tanks hardly

seem to get out of the factory without bending or tearing off the sheet

metal! housings

up with the hull-side pieces too well; there's supposed to be a step

there, but I sanded it flush. The fenders are rather thin but still

not scale thickness, so I scraped and sanded them down, and then carefully

bent them up by heating them with a candle and applying some needle-nose

pliers. It's easy to do but easy to mess up as well. Too much heat and

they melt, and the pliers sometimes leave marks that have to be filled.

This method tends to round the corners on the fenders a bit, but if

you are careful it's nothing a few swipes with the edge of a hobby knife

won't fix. Also I cut off one of the front fenders. Soviet tanks hardly

seem to get out of the factory without bending or tearing off the sheet

metal!

Now,

on to the screen and cover at the back of the engine deck. This is where

air which has been sucked through the engine's radiators is ejected

by a big centrifugal fan. In the few photos which show this screen clearly,

it's obviously a rather light mesh and quite transparent. The molded

screen isn't bad, but it isn't transparent either, so I decided I'd

like to replace the screen with a real screen. It would have been better

had I decided this before assembling the hull, of course, but oh well!

That's what you get if you don't plan things out thoroughly in advance.

I cut the cover containing the screen off with a razor saw and filled

the resulting ugly hole with Green Stuff. I produced some rather simplistic

dampers; nothing sophisticated is required, since you won't be able

to see them very well under the mesh. I thought I could use the appropriate

part off the Esci kit, but of course it was a different size and shape

and no use at all, so I scratched a replacement, twice as a matter of

fact since the first one was no good. In the end the outside part was

carved from plastic sheet and the individual mullions were made from Now,

on to the screen and cover at the back of the engine deck. This is where

air which has been sucked through the engine's radiators is ejected

by a big centrifugal fan. In the few photos which show this screen clearly,

it's obviously a rather light mesh and quite transparent. The molded

screen isn't bad, but it isn't transparent either, so I decided I'd

like to replace the screen with a real screen. It would have been better

had I decided this before assembling the hull, of course, but oh well!

That's what you get if you don't plan things out thoroughly in advance.

I cut the cover containing the screen off with a razor saw and filled

the resulting ugly hole with Green Stuff. I produced some rather simplistic

dampers; nothing sophisticated is required, since you won't be able

to see them very well under the mesh. I thought I could use the appropriate

part off the Esci kit, but of course it was a different size and shape

and no use at all, so I scratched a replacement, twice as a matter of

fact since the first one was no good. In the end the outside part was

carved from plastic sheet and the individual mullions were made from

very

thin sheet aluminum. The generous Mr. Bill Glinski gave me some screen

for it. It's not easy to cut, as the grain of the screen is on a diagonal

with the rest of the cover. Then came the hardest part; after finally

assembling a good looking cover and screen, I gently crushed it with

my fingers. It was a shame, but the real things almost always look like

they've been trampled by heavy-footed Soviet desantniki (armored infantry). very

thin sheet aluminum. The generous Mr. Bill Glinski gave me some screen

for it. It's not easy to cut, as the grain of the screen is on a diagonal

with the rest of the cover. Then came the hardest part; after finally

assembling a good looking cover and screen, I gently crushed it with

my fingers. It was a shame, but the real things almost always look like

they've been trampled by heavy-footed Soviet desantniki (armored infantry).

On mid-production T-34's like this one, with hexagonal turrets, there

are two different kinds of grab handles. There are straight tubes held

on with sheet metal brackets, and tubes bent so the ends could be welded

directly to the hull. Of course, the first is much more difficult to

model, and of course it is much more common on the real T-34's. I went

for the easy solution, and installed the bent tubes out of brass wire.

The

wheels were a major project all by themselves. Just to be different,

I wanted one of the 1942-43 tanks with a mixed arrangement of wheels

with and without tires. (This is the result of rubber shortages; at

the beginning of the war, T-34's have all rubber-tired wheels, but when

the rubber started to run out, they devised an all-steel wheel. Unfortunately,

this caused so much vibration at speed that parts would get shaken off

the tank, so a compromise arrangement was made, with rubber tires at

bow and stern and all-steel wheels in the middle. This is what I wanted

to duplicate.) The Esci kit had all-steel wheels and fortunately these

are exactly the same diameter as the Eastern Express's wheels. I had

to drill the back of the Esci wheels and install stub axles to match

the Eastern Express hull. This was a fragile connection, but nothing

better presented itself. The Esci wheels were OK…but after I looked

at them a while they became less and less OK. They were just too crude

a representation, and finally I could not stand it any more. I ripped

them off and started over. I thinned down the rims first, with a new

Exacto blade and a roll of sandpaper, and I cut the axle dome out of

the center. I drilled out the lightening holes to a proper diameter.

Then I replaced the center dome with a plastic disk punched out with

a set of The

wheels were a major project all by themselves. Just to be different,

I wanted one of the 1942-43 tanks with a mixed arrangement of wheels

with and without tires. (This is the result of rubber shortages; at

the beginning of the war, T-34's have all rubber-tired wheels, but when

the rubber started to run out, they devised an all-steel wheel. Unfortunately,

this caused so much vibration at speed that parts would get shaken off

the tank, so a compromise arrangement was made, with rubber tires at

bow and stern and all-steel wheels in the middle. This is what I wanted

to duplicate.) The Esci kit had all-steel wheels and fortunately these

are exactly the same diameter as the Eastern Express's wheels. I had

to drill the back of the Esci wheels and install stub axles to match

the Eastern Express hull. This was a fragile connection, but nothing

better presented itself. The Esci wheels were OK…but after I looked

at them a while they became less and less OK. They were just too crude

a representation, and finally I could not stand it any more. I ripped

them off and started over. I thinned down the rims first, with a new

Exacto blade and a roll of sandpaper, and I cut the axle dome out of

the center. I drilled out the lightening holes to a proper diameter.

Then I replaced the center dome with a plastic disk punched out with

a set of  Waldron

punches (happily one punch exactly matched the required diameter) and

started installing the radial gussets. I couldn't cut and install these

tiny bits in the proper size so what I did was cut them oversize, glue

them in place, and after the glue was dry I cut them down with a new

Exacto blade. The dome over the bearing, and the nuts, I built up with

layers of white glue. I've got to find a better technique; this one

is OK but in the end I just can't seem to get things as even and uniform

as I'd like. Waldron

punches (happily one punch exactly matched the required diameter) and

started installing the radial gussets. I couldn't cut and install these

tiny bits in the proper size so what I did was cut them oversize, glue

them in place, and after the glue was dry I cut them down with a new

Exacto blade. The dome over the bearing, and the nuts, I built up with

layers of white glue. I've got to find a better technique; this one

is OK but in the end I just can't seem to get things as even and uniform

as I'd like.

If I ever need all-steel wheels again, I'll either buy them from Al-By

or make one really good one and get it cast. This was just too tedious

to do again. Also, the all-steel wheels make one of the kit's flaws

easier to see; the rear three wheels are a bit too close together. Fixing

that would very difficult, so I let it ride.

People

naturally associate the T-34 with those cylindrical fuel tanks on the

sides of the rear hull, but these types of fuel tanks were rather later

in the war. To be a little different, I wanted the square-ish sheet

metal tanks over the rear fenders, as represented on the Esci kit. I

used the Esci parts, but I had to modify their shape somewhat, since

the Esci kit's rear hull is at a different angle than that on the Esci

kit. I glued on a wedge of plastic to make up the difference. People

naturally associate the T-34 with those cylindrical fuel tanks on the

sides of the rear hull, but these types of fuel tanks were rather later

in the war. To be a little different, I wanted the square-ish sheet

metal tanks over the rear fenders, as represented on the Esci kit. I

used the Esci parts, but I had to modify their shape somewhat, since

the Esci kit's rear hull is at a different angle than that on the Esci

kit. I glued on a wedge of plastic to make up the difference.

The unditching log is a twig. When I first tried this out on my model,

it was too realistic, which is to say it looked like a twig. I tried

repainting it, a blotchy white-to-pale-gray coat with a random pattern

of circumferential dark gray stripes reproduced a birch log very well,

and I was most pleased with the effect.

The

Eastern Express kits comes with four ends for the tow cables. You have

to supply the cables for yourself. I was going to use a thread, stiffened

with white glue, but I had no thread of the right thickness. Then I

had a brainstorm and took three threads and twisted them together, clamped

on each end to hold them in place. I soaked in some diluted Elmer's

glue and after that dried I painted over the outside with a dark reddish-brown

paint. Together, these stiffened the cable to the point where it remained

twisted after the ends were unclamped. Actually, this was better than

simple thread; the three-strand arrangement is more visible and it looks

very much like real steel cable. The

Eastern Express kits comes with four ends for the tow cables. You have

to supply the cables for yourself. I was going to use a thread, stiffened

with white glue, but I had no thread of the right thickness. Then I

had a brainstorm and took three threads and twisted them together, clamped

on each end to hold them in place. I soaked in some diluted Elmer's

glue and after that dried I painted over the outside with a dark reddish-brown

paint. Together, these stiffened the cable to the point where it remained

twisted after the ends were unclamped. Actually, this was better than

simple thread; the three-strand arrangement is more visible and it looks

very much like real steel cable.

This was my first experience with link-and-length tracks. While the

results look good (especially on a T-34, rubber-band tracks never cut

it) they were a lot of effort. The plastic is very brittle and it is

difficult to work the lengths into a curve, to duplicate the slight

sag between each wheel. I tried heating the tracks in hot water but

this had little effect. Eventually I managed to get the lengths to curve

without breaking by heating them over a light bulb, though even then

it took several applications to get any reasonable curve. I'd really

rather have 100% individual links than the lengths. Also, of course

the number of links didn't come out even. I managed to work in a partial

link on the top run on top of a wheel, where there is so little room

below the fenders it can't be seen. Next time I hope for a better and

easier effect, but even with all the problems the appearance is better

than rubber-band tracks.

The

single headlight is drilled out and a disk of aluminum foil is glued

inside; then a drop of epoxy glue makes the glass. The

single headlight is drilled out and a disk of aluminum foil is glued

inside; then a drop of epoxy glue makes the glass.

The vehicle is painted in Humbrol's Deep Bronze Green very heavily

drybrushed with Pactra Light Olive Drab. The whole vehicle is drybrushed

with Humbrol Panzer Yellow, for dirt and highlighting, then lightly

drybrushed again with more Light Olive Drab to tone down the overemphasized

corners. I painted the tracks while still on the sprue, and then retouched

them after installation; dark reddish brown with a drybrushing of a

lighter, more red brown. I used a silver colored pencil to highlight

the raised details on the tracks, and that looked very good. The spare

tracks are painted much more rusty, since they don't have the rust rubbed

off through use.

I

am becoming more and more inclined to think that good figures are necessary

to set off a good model. The commander is an Esci figure with some Preiser

luftwaffe legs. He looked pretty good. I bent his hands to grip the

hatch cover. The driver is a magnificent AB figure, but fortunately

it's difficult to see him. Fortunately, because he'd make the commander

figure look bad if you could compare them. I

am becoming more and more inclined to think that good figures are necessary

to set off a good model. The commander is an Esci figure with some Preiser

luftwaffe legs. He looked pretty good. I bent his hands to grip the

hatch cover. The driver is a magnificent AB figure, but fortunately

it's difficult to see him. Fortunately, because he'd make the commander

figure look bad if you could compare them.

Conclusion

So there you are! I'm quite pleased with the final results, though I

could have got there by an easier route. I might not build 35,000 like

the Soviet government, but I'll build a few I'm sure.

|

|